Deco 3000 ATT – The AMF Reece handstitching machines add value to any type of outwear and are especially required by manufacturers sewing top quality garments such as men’s/ladies’ tailored jackets, suits, leather garments etc.

AMF Reece specialty industrial sewing machines are used in variety of applications. You can see the overview of our main applications.

AMF Reece – Cars, before AMF REECE, has long experience in manufacturing and developing pocketwelting machines. AMF Reece pocket welting machine Series 42 introduced in the 60s became the world’s first automatic pocket welting machine. Since that company has successfully sold a number of pocket welting machines. Currently AMF Reece -Cars offers lockstitch pocketwelting machine LW 7001 that efficiently sews single, double straight and slanted (angle) welts depending on the machine modification. This versatile lockstitch pocketwelting machine can be used for all types of welted pockets and is ideal for all segments of the apparel industry. Available models and a wide range of optional accessories make the lockstitch…

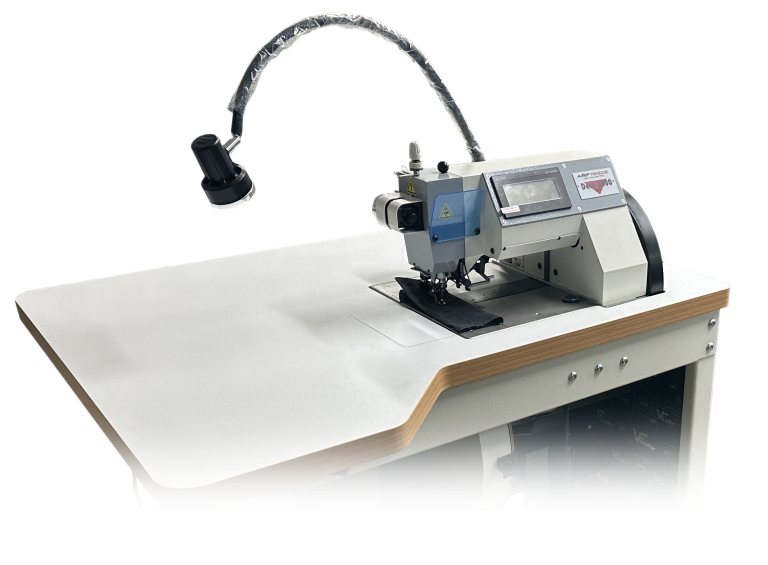

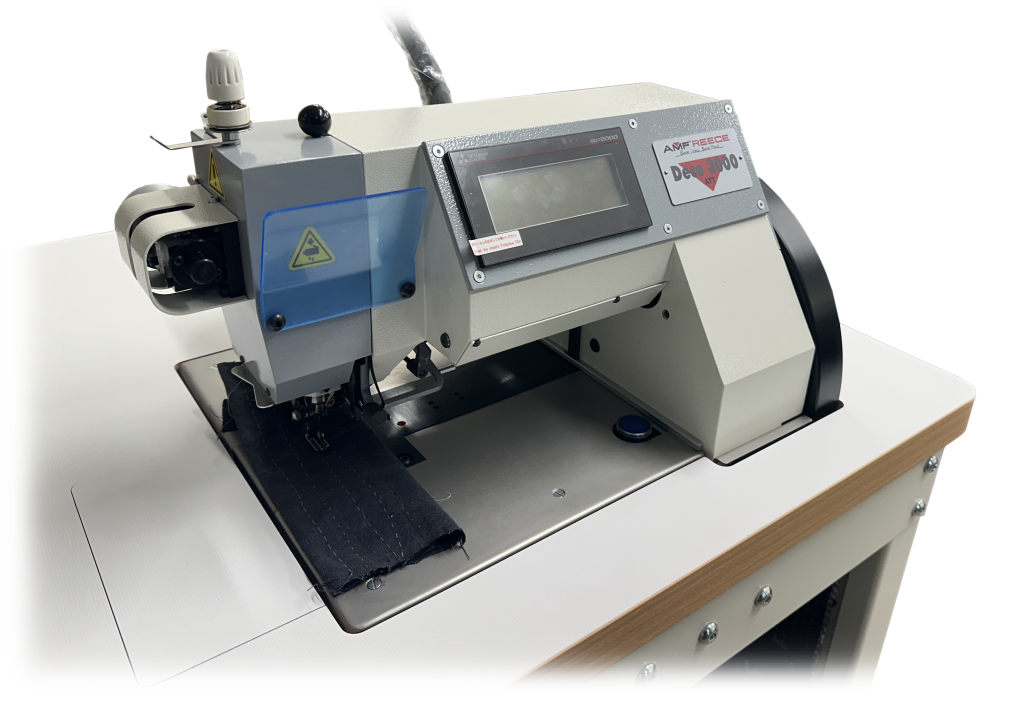

The AMF Reece handstitching machines add value to any type of outwear and are especially required by manufacturers sewing top quality garments such as men’s/ladies’ tailored jackets, suits, leather garments etc. This handstitching machines are equipped with our unique and patented floating needle technology. The handstitching machines use a double pointed needle with an eye in the middle. By the use of two needle bars, a length of thread is passed through the material duplicating the hand stitch with flawless consistency and incomparable speed. Due to the hand-sewn effect the handstitching machines are presented as the hallmark of quality.

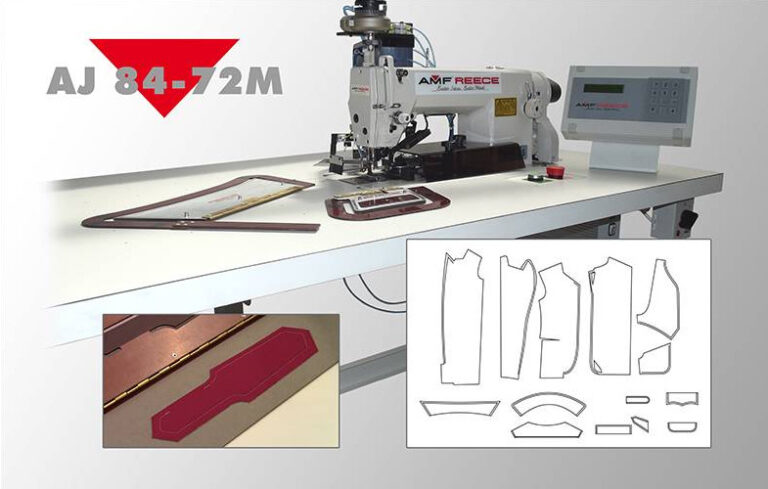

The Automatic templates stitching system, was pioneered by our company in the 1960’s. The automatic templates stitching system enables large and small garment components to be assembled quickly and accurately by unskilled operators, without the high cost and inflexibility normally associated with automatic system. The patented AMF Reece automatic templates stitching system ensures that the stitched component has perfect size, shape and “fullness,” irrespective of the operator’s skill, for the maximum quality. Component size or shape can be changed in the few seconds required to exchange the stitching jigs. Automatic templates stitching system offers a range of models…

The S-4000 AMF Reece series is the most productive chainstitch special application machine line available with no bobbin changes and the only one with an electronic stop motion. The S-4000 series offers seven different machines depending on the application such as – straight buttonhole machine, imitation sleeve buttonhole machine with Indexer, tacker machine, lingerie tacker machine, cut after edge machine, label sewer machine and single row with dot. The high, electronically selectable sewing speed up to 3,800 spm makes the S-4000 the fastest chainstitch buttonhole and special applications machines available. The elasticity of chainstitch provides the flexibility needed for many fabrics such as…

AMF Reece – Cars s.r.o.

Tovární 837/9C

798 11 Prostějov

Czech Republic